We’re always working to advance the life science, industrial, and medical research fields by engineering high-quality optical equipment, components, and parts. One way we do this is by providing image analysis and microscope-based imaging system manufacturers with the latest high-performance objectives to integrate into their devices.

Our conversations with manufacturers often reveal that they have difficulty ensuring that their devices provide uniform quality images. Even manufacturers that design high-performance devices will fail to achieve the quality, cost, and lead time they promised if significant variations or errors occur in their manufacturing processes due to the performance of integrated microscope objectives. It’s conversations like these that push us to continue innovating.

Our latest imaging breakthrough is X Line objectives. We launched them in 2019, breaking traditional imaging barriers by delivering high levels of numerical aperture, chromatic aberration correction, and flatness at the same time—three critical parameters traded off against each other in the past. We also adopted wavefront aberration control for these objectives, offering imaging analysis and microscope manufacturers a solution to problems stemming from variations in objective performance

The standard way an objective’s optical performance is measured is the Strehl ratio. This is the ratio, expressed as a percentage, of the convergence ratio attainable in an actual optical system with aberrations to the convergence ratio (or the intensity at the center) in the image field of an ideal aplanatic optical system. This means the higher the Strehl ratio, the higher the optical system’s quality. As an example, our MPLAPON50X and MPLAPON100X objectives have a Strehl ratio of 95% or higher.

So, why is wavefront aberration so important? Read on to find out.

How Wavefront Aberration Control Reduces Objective Performance Variations

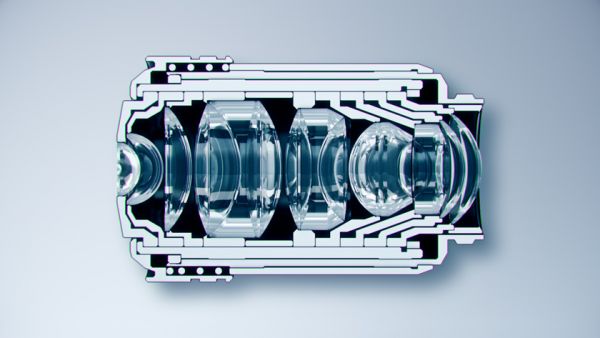

Performance improvements in microscope objectives have led to a more complex and miniaturized internal lens structure (Figure 1). As a result, objectives tend to have differences in quality due to manufacturing errors, and sometimes these differences cause variations in a final product’s performance.

To minimize the chance of these kinds of variations, Olympus technicians measure the wavefront aberration during the assembly processes for X Line and some other types of objectives. Wavefront aberration is caused by the deviation of the formed image from the ideal one and is controlled as a quality parameter.

|  |

Figure 2: Olympus technicians inspect the wavefront aberration of microscope objective lenses. |

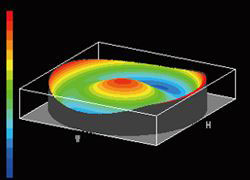

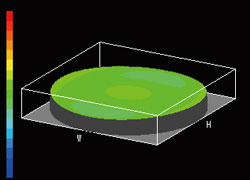

By measuring and controlling the wavefront aberration of each objective to bring it closer to its ideal state (aberration-free), we produce objectives with much less variation in optical performance compared to conventional objectives (see Figure 3 (a) below). The result is consistent quality, as shown in Figure 3 (b).

(a) Aberrated wavefront (conventional objective). |

(b) Nearly aberration-free wavefront (X Line objective). |

Figure 3: Examples of wavefronts. |

3 Reasons to Integrate Objectives with Wavefront Aberration Control into an Imaging Device

Here are the top reasons to integrate objective lenses with wavefront aberration control into your microscope design:

- Produces stable, high-quality images

The image quality affects how quickly and accurately a device's software can measure it. Objectives with wavefront aberration control can provide stable and high image quality, so if reliability matters in your final product, integrating an objective with wavefront aberration control is a must. - Reduces costs

An imaging device that fails to work properly due to objective performance variations will incur extra costs. For instance, you may need to discard the objective and buy a replacement. Objectives with wavefront aberration control can reduce these costs due to their high performance. - Stabilizes your product delivery schedule

A device that’s expected to deliver high performance will need extra adjustments to cope with objective performance variations. This can mean a longer production lead time. In contrast, adopting objectives designed with wavefront aberration control for consistent quality means you can deliver devices on promised delivery dates. Plus, you can keep a backup inventory of dependable objectives.

Related Content

Brochure: OEM Microscope Component Solutions