New Imaging Possibilities Using the World's First Multi-Immersion Silicone Gel Objective

Combining the ease of dry objective lenses with the optical performance of immersion lenses.

Introduction

The objective lens is the key component that determines the optical performance of a microscope. Traditionally, two types of objectives have been available: dry lenses and immersion lenses. Immersion objectives are widely used in life science research due to their ability to capture high-resolution and bright images.

However, users often report several challenges associated with immersion objectives:

- Using an immersion objective with a multi-well plate is cumbersome and complicated.

- Applying immersion liquid is difficult when using a stage-top incubator for long-term time-lapse experiments.

- Switching from high‑magnification immersion lenses for detailed observation to low‑magnification dry lenses for macro observation contaminates the dry one with immersion liquid.

- Cleaning the microscope and specimens after using immersion oil is a hassle.

To address these challenges, Evident developed the world’s first multi-immersion silicone gel objective. Featuring the LUPLAPO25XS objective lens and SILGEL-L25 silicone gel pad, this breakthrough technology combines the ease of dry objectives with the optical performance of immersion lenses.

This white paper explores these technologies in detail, highlighting the advantages of this unique objective lens system compared to conventional lens types.

Objective Lens Types

Microscope objectives fall into three categories:

1. Dry objective lenses

Dry lenses operate with air between the objective lens and the sample, making them easy to use. They are suitable for observation at low magnification and for wide-area observation by stitching together multiple images captured at high magnification. They also enable smooth transitions between macro and micro observations.

2. Immersion objective lenses

These lenses employ a liquid medium—typically silicone oil or water. Immersion lenses can be designed with high numerical aperture (NA) optics that deliver a high signal-to-noise ratio (SNR) and high-resolution images.1 By using an immersion liquid that matches the refractive index of the biological sample, spherical aberrations can be reduced in deep observation, and bright and high-resolution images can be acquired.

3. Silicone gel objective lenses

Using a semi‑solid silicone gel pad rather than liquid, these lenses maintain optical clarity without the drawbacks of liquid handling. The gel is stable and unaffected by the external environment, so it maintains moisture for reliable performance even in long-term imaging experiments.

Table 1. Comparison of Objective Lens Types and Performance

| Dry objective | Immersion objective | Silicone gel immersion objective | ||

|---|---|---|---|---|

| Optical performance | High SNR observation | ○ | ◎ | ◎ |

| High-resolution observation | ○ | ◎ | ◎ | |

| Reduced depth crosstalk | ○ | ◎ | ◎ | |

| Operational Performance | Macro ↔ micro switching | ◎ | △ | ◎ |

| Wide-area stitching/multipoint observation | ◎ | △ | ◎ | |

| Image acquisition stability | ◎ | △ | ◎ | |

| ○ Good performance; ◎ Very good performance; △ Has challenges. | ||||

Challenges of Using Conventional Immersion Objective Lenses

While offering high magnification and resolution, conventional immersion objective lenses present several challenges.

1. Complicated lens switching

When starting with a low-magnification dry lens to position the specimen and switching to an immersion lens for observation, several issues may occur: loss of the focus position, air bubbles in the immersion solution, or an insufficient immersion medium.

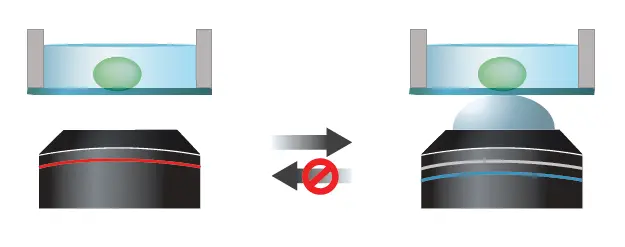

When these issues occur, users must temporarily halt observation and clean the container and objective lens. This wastes labor and time, and it may negatively impact the specimens. For example, removing specimens from the stage-top incubator may cause damage to them. For specimens floating in the culture medium, the cleaning process may cause the specimens to shift, which may affect the reproducibility of the experiment. This leads to a case where the dry lens cannot be used after using the immersion one (Figure 1).

Ideally, it should be possible to switch between immersion and dry lenses without changing the specimen position, just like when switching between dry lenses, enabling imaging to run smoothly without interrupting observation.

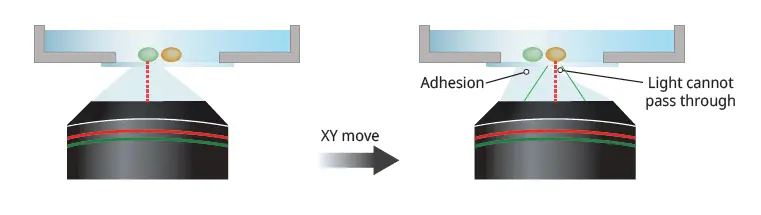

Figure 1. It is possible to switch from a dry lens (left) to an immersion lens (right), but not the other way around as liquid remains on the specimen after immersion use.

XY observation range constraints

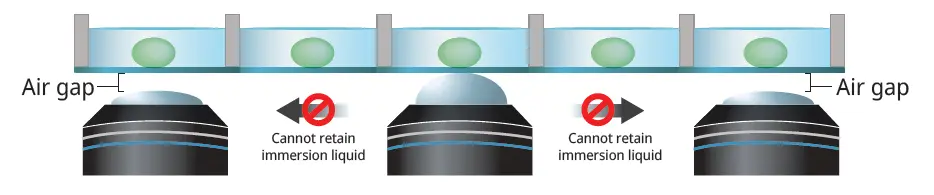

With immersion objective lenses, when the stage is moved beyond a certain range in the XY direction during specimen observation, the immersion liquid fails to follow the objective lens, causing the liquid to run out and making widefield observation impossible (Figure 2).

Figure 2. The immersion liquid runs out when the stage moves to another position, causing an air gap between the objective lens and specimen.

In recent years, there has been a growing demand for efficient observation of a large number of spheroids and organoids in multi-well plates. However, the limited XY observation range of immersion lenses makes it difficult to smoothly observe multiple wells in a plate, and dry lenses are unsuitable when deep observation is required..

Ideally, the system should be able to freely perform imaging over a wide area and multipoint observation at any position without concern for XY observation range restrictions.

3. Unstable retention of the immersion solution during prolonged imaging

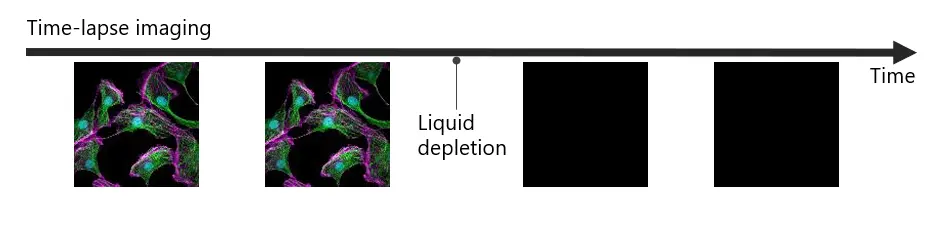

During extended imaging experiments, image acquisition may fail due to air bubbles or an insufficient immersion solution caused by the external environment (Figure 3). If this issue leads to re-experimentation or recreation of specimens, the efficiency of the research is greatly reduced.

Ideally, the system should be able to stabilize immersion retention and perform imaging for extended periods of time without being affected by the external environment.

Figure 3. Immersion liquid can run out during time-lapse imaging, leading to data loss.

To overcome these challenges with immersion objective lenses, we focused on innovating semi-solid gels instead of liquids. This led to the development of an objective lens using silicone gel as the immersion material.

Developing a Silicone Gel Immersion Objective Lens

There were three technical hurdles in designing an objective lens that uses a semi-solid gel as its immersion medium.

1. Developing the optimal gel substrate

The following properties are required for a gel to be suitable for microscopic imaging.

- Optical properties: refractive index, Abbe number, autofluorescence, transmittance

- Mechanical properties: hardness, durability, low adhesion to containers

Since the gel is pressed against the specimen during imaging, it is important that the optical properties, such as refractive index and Abbe number, remain the same before and after compression.

In addition, a material with low autofluorescence is essential to obtain fluorescence images with good SNR. The material must be soft and easily deformable for deep observation, but hard enough to return to its original shape without leaving gel residue in the container when the gel is removed from the specimen. Through a trial-and-error process of selecting the gel material, including optimizing the formulation conditions and shape, we succeeded in developing Evident's patented silicone gel pad technology that satisfies both optical and mechanical properties (Figures 4 and 5, Table 2).

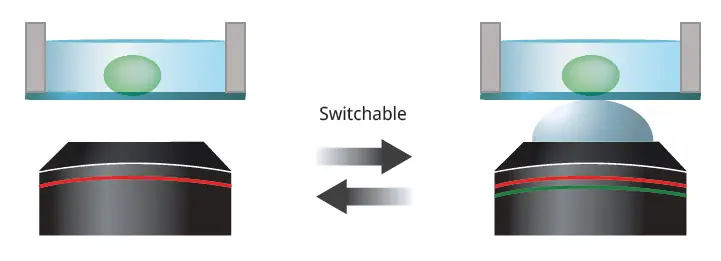

Figure 4. Dry (left) and silicone gel pad (right) objectives can be easily switched.

Figure 5. Container appearance after gel adhesion leaves no gel residue on the container, so the cleaning step is eliminated.

Table 2. Evident’s Silicone Gel Properties for Microscopic Imaging

| Gel Properties | Advantages for Microscopic Imaging | |

|---|---|---|

| Optical Properties | Optical performance equivalent to silicone oil |

|

| Mechanical Properties | Flexible and durable gel material |

|

| Stability/Safety | Maintains properties in safe materials |

|

Frictional properties of the gel and container

Although silicone gel is an excellent material with both optical and mechanical properties, a certain frictional force exists between the gel and specimen. Therefore, if the specimen is moved in the XY direction beyond a certain range, a portion of the gel separates from the cover glass and a portion of the light does not pass through the immersion medium, resulting in image quality degradation (Figure 6).

Figure 6. If part of the silicone gel detaches from the cover glass after XY movement, then some light cannot pass through the immersion medium, impacting image quality.

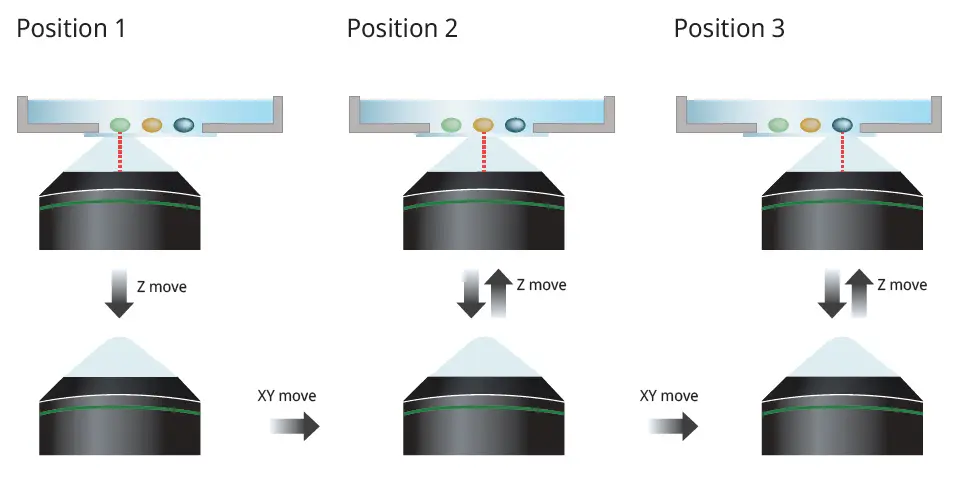

To solve this issue, the cellSens™ software of the IX85 automated inverted microscope system is equipped with a control function dedicated to silicone gel immersion observation.

The risk of image quality deterioration is minimized by using the following automated control method: the silicone gel pad lens is removed from the specimen during XY movement (escape), the XY movement is performed, and the silicone gel pad lens is placed in close contact with the specimen again (Figure 7).

Figure 7. The silicone gel pad moves with the objective lens during multipoint acquisition.

The silicone gel pad lens and this control method enable high-quality images with a wide field of view, high signal-to-noise observation, high-resolution observation, and depth observation. These capabilities are advantageous, for example, in the observation of spheroids and organoids cultured in multiple wells of a multi-well plate, which requires imaging multiple points and a wide area. This method enables screening with high image quality.

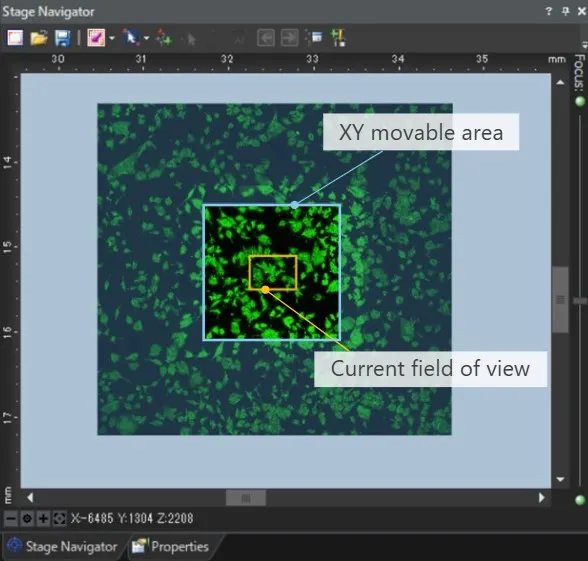

The software's stage navigator displays the range that can be observed with a silicone gel immersion objective without escaping Z (Figure 8). This makes it possible to use the stage while knowing the observable area, minimizing the risk of going outside the range and impacting the gel immersion medium. As a result, users can capture high-quality images with confidence.

Figure 8. Visualization of the area observable with a silicone gel objective.

Establishment of a High-Quality Gel Production Method

Imaging gels must be of high quality. Contamination of foreign matter or bubbles leads to images with low signal-to-noise ratios, while rough gel surfaces significantly reduce durability performance and increase wear frequency. However, since there was no existing gel suitable for imaging applications, it was necessary to establish a manufacturing method from scratch and build a stable production system.

To give a simplified overview of the gel manufacturing method, the silicone gel solution is poured into a mold, cured, and then removed from the mold to be manufactured. A particular challenge was the surface precision of the gel. It is not enough to make the surface of the mold high precision. Through repeated studies, selection of a mold material suitable for the gel material, and optimization of the material and mold temperature conditions, it became possible to manufacture gels with a high-precision surface comparable to the surface of a lens.

To eliminate foreign matter and air bubbles, a high-class cleanroom environment was established at a level comparable to that used in the manufacture of optical elements. In addition, by setting strict inspection standards, we have established a production line that ensures consistent quality. These manufacturing environments have enabled us to achieve mass production of a high-quality silicone gel with stable and consistent optical and mechanical properties.

Development of a Multi-Immersion Objective Lens

In addition to the development of silicone gel, we used the lens polishing and assembly techniques from our renowned X Line™ series to develop a compatible objective lens: the LUPLAPO25XS. This special multi-immersion lens can be used with both our silicone gel pad technology and liquid forms by changing the attachment on the tip of the objective lens (Figure 9).

Figure 9. Silicone gel immersion (left) and water immersion (right) objective lenses.

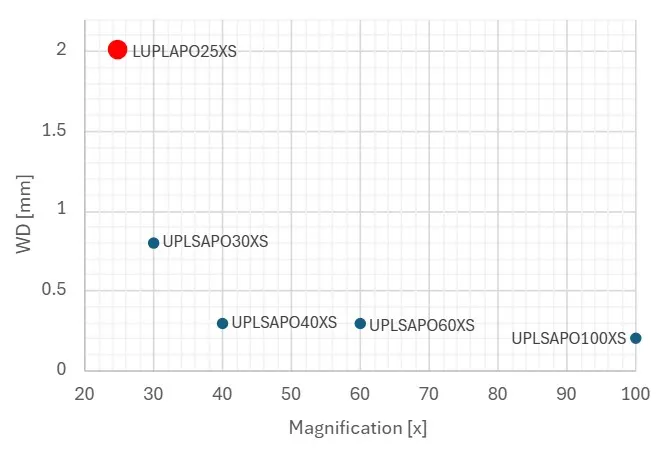

The LUPLAPO25XS currently has the widest observation range (actual field of view is approximately 1 mm) and longest working distance (WD: 2 mm) of our silicone immersion objective lenses (Figure 10). The lens can also correct the refractive index from water to silicone oil (refractive index: 1.33 to 1.40).

Figure 10. Working distance and magnification of Evident’s silicone immersion objective lenses.

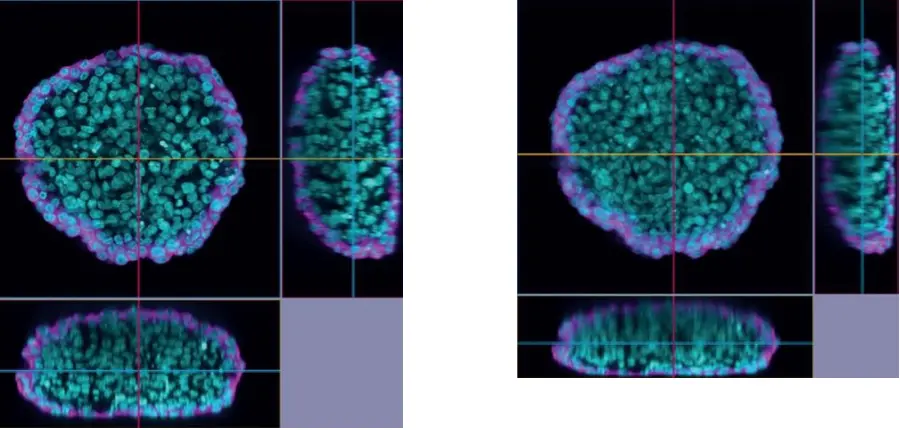

The wide field of view, long working distance, and refractive index range required for specimens in culture enable clear observation of spheroids and organoids over a wide area and down to a depth of 1 mm. The image below is a comparison of a dry objective lens with a similar NA (Figure 11), and it can be confirmed that silicone gel immersion allows clear observation of spheroids to a depth of 1 mm.

Figure 11. XYZ image comparison. Left: LUPLAPO25XS silicone gel pad objective, NA 0.85. Right: UPLXAPO20X dry objective, NA 0.8. Cleared HeLa* 1 cell spheroid (cyan: nuclei, magenta: microtubules). Captured on the IXplore IX85 Spin spinning disk confocal microscope. *To learn more about the origin of HeLa cells, visit henriettalacksfoundation.org.

Summary

By developing the world's first multi-immersion silicone gel objective lens, we have successfully solved the potential challenges of using immersion objective lenses. This innovative lens technology offers several key advantages:

- High-quality images via high SNR observation, high-resolution observation, and depth observation without limitation of the XY observation range.

- Smooth lens switching between the gel pad objective and a dry objective, improving the workflow of imaging experiments.

- Reduced maintenance with no specimen or microscope contamination from the gel pad technology.

By facilitating the stable acquisition of high-quality imaging data, the multi-immersion silicone gel objective lens will contribute to improving the quality and efficiency of life science research.

References

1. Samuelsson, Andrew. “Silicone Immersion Objectives Answer the Call for Higher Resolution.” EvidentScientific.com. Originally published on Photonics Spectra. Accessed July 1, 2025.

Author

Kengo Osawai

Micro-Imaging Solutions R&D, Imaging Optics

Evident, Japan

Products Related to This Application

was successfully added to your bookmarks

Maximum Compare Limit of 5 Items

Please adjust your selection to be no more than 5 items to compare at once

Not Available in Your Country

Sorry, this page is not

available in your country.