Automated Spherical Aberration Correction for High-Resolution, High-Contrast Fluorescence Imaging

Introduction

Fluorescence microscopes are widely used in life sciences and medical research for morphological observation and quantitative analysis of cells and other biological samples. Objective lenses for biological microscopes are generally designed with the assumption that a standard cover glass of 0.17 mm thickness is in close contact with the specimen.

However, when using high numerical aperture (NA) objective lenses, slight differences—such as variations in cover glass thickness or deeper sample positioning—can cause spherical aberration, deteriorating the image quality. Many of these high NA objective lenses are equipped with a correction collar, also known as a correction ring, to adjust for spherical aberration according to the cover glass thickness. Fine-tuning the objective correction collar is essential to achieve optimal image clarity.

The IXplore™ IX85 inverted microscope platform by Evident automates this process through intuitive software and a motorized correction collar. With the click of a button in cellSens™ software, the platform uses an electric correction ring control mechanism to automatically adjust the collar for a wide range of high NA objectives. This automated objective correction system enables efficient acquisition of clear images with reduced spherical aberration and high resolution and contrast.

Figure 1. Motorized correction collar on the IXplore IX85 inverted microscope platform.

The Challenges of Spherical Aberration Correction

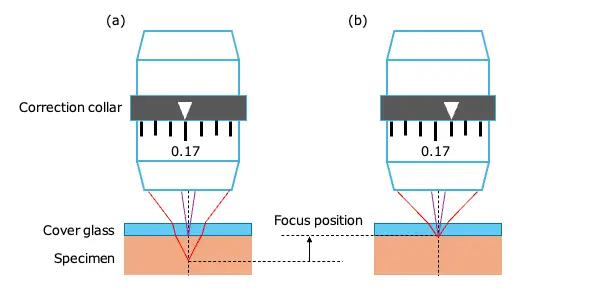

When the cover glass thickness deviates from the standard design of 0.17 mm, the central and peripheral light rays passing through the objective lens do not converge at the same focal point, leading to a decrease in resolution and contrast. This phenomenon is known as spherical aberration, and it can be corrected by turning the correction collar to align the focal positions of the light rays (Figure 2).

The process presents several challenges. First, the correction collar and focus must be fine-tuned simultaneously to find the position where the image is the clearest. Second, determining the point of best correction often requires comparing multiple images to detect small improvements in clarity. This involves turning the ring, adjusting the focus, evaluating image clarity, and repeating the process to identify the ideal correction position on the collar. Microscope users need expertise to make these precise adjustments, limiting the ability to achieve high reproducibility between experiments.

Manual adjustments are also time-consuming—an issue in fluorescence imaging where photobleaching can degrade the sample during prolonged exposure. Signal levels may already be low in fluorescence imaging, so maintaining high contrast through quick and precise spherical aberration correction is essential for accurate visualization and analysis.

Figure 2. Concept of spherical aberration correction using an objective correction collar. a) Focus position where spherical aberration occurs. b) Focus position where spherical aberration is corrected.

Introducing an Automated Spherical Aberration Correction Method

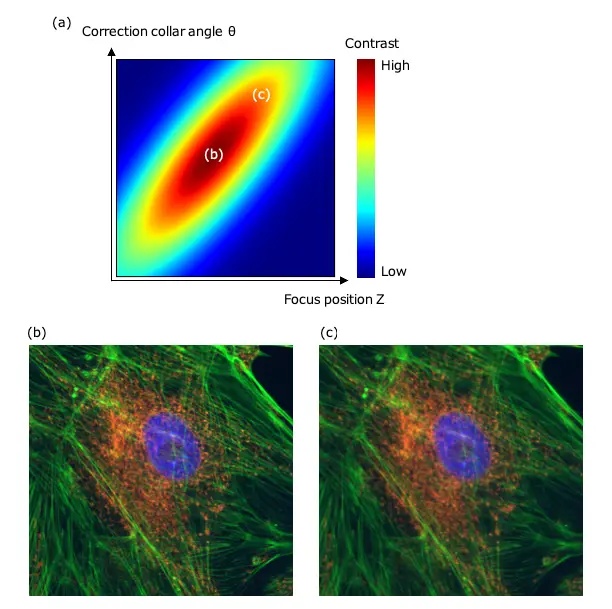

Image clarity can be expressed by the strength of the image contrast. As the correction collar angle and focus position change, the resulting image contrast forms a slanted, mountain-like shape, as illustrated in Figure 3a. The peak of this shape (Figure 3b) is the most corrected state of spherical aberration, and adjusting the correction collar is the same as finding this peak position. If the correction is insufficient, where it deviates from the peak (Figure 3c), the image will be blurred even if the focus is correct.

Figure 3. Contrast variations with the correction collar angle and focus position. a) Heat map of the relationship between the correction collar angle, focus position, and contrast. b) Fluorescence image with the highest contrast obtained by adjusting the correction collar. c) Fluorescence image with an unadjusted correction collar in the same Z-position as (b).

Creating such a heat map typically requires acquiring multiple images while varying the correction collar and focus. This process is time-consuming and causes the specimen to fade during fluorescence observation, which affects the contrast value and compromises accuracy. Therefore, automated spherical aberration correction must be fast and accurate to minimize fading.

The newly implemented automated spherical aberration correction for fluorescence observation on the IXplore IX85 platform with cellSens software adopts the Nelder-Mead method, enabling efficient adjustment of the focus position and correction collar angle.

The contrast heat map varies in the gradient and spread depending on the objective lens. However, the Nelder-Mead method is robust against the shape of the optimization target function and can be applied even if it is nonlinear. This makes it suitable for adjusting the heat map defined for each objective lens.

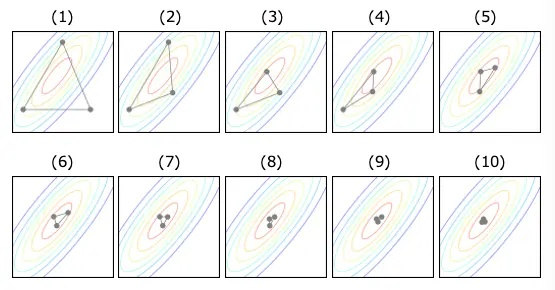

The search for maximum contrast is performed by updating three points called a simplex. First, the contrast is obtained at the initial three points, as shown in Figure 4 (1). Then, the position of the point with the lowest contrast is updated (2). The process of updating one or two points is repeated, shortening the simplex interval and ending the search when it falls below the convergence criterion, as shown in (3) to (10). By narrowing the search range adaptively rather than exploring the entire area at once, this method makes it possible to approach the position with the highest contrast efficiently without unnecessary imaging steps.

The Nelder-Mead method has the advantage of adjusting the search quickly compared to an exhaustive search for the maximum contrast. Under test conditions using a UPLXAPO40X objective lens and a camera exposure time of 200 milliseconds, the Nelder-Mead method takes about 20 seconds. In contrast, the conventional exhaustive method takes about 45 seconds to derive the position with the highest contrast. This method takes longer as it divides the correction collar angle θ into 10 parts and Z into 10 parts, covering 100 points comprehensively. The comparison demonstrates that the automated method reduces adjustment time by more than 50 percent.

Figure 4. Adjustment process via the Nelder-Mead method.

Summary

The motorized correction collar and automated adjustment algorithm on the IXplore IX85 platform enable precise and fast spherical aberration correction, which is often challenging to achieve manually. Automated spherical aberration correction also minimizes photobleaching in fluorescence microscopy with quick, precise adjustments. The collar is seamlessly integrated with the IX85 system, easily controlled through cellSens software, and compatible with a wide range of Evident’s standard objectives. This innovation enables users of varying skill levels to acquire clear fluorescence images with high resolution and contrast.

Author

Motohiro Shibata

Micro-Imaging Solutions R&D, Imaging Systems and Technology

Evident, Japan

Products Related to This Application

was successfully added to your bookmarks

Maximum Compare Limit of 5 Items

Please adjust your selection to be no more than 5 items to compare at once

Not Available in Your Country

Sorry, this page is not

available in your country.